Commutating reverse polarity power supplies are specialized power sources capable of dynamically switching output voltage polarity. They are commonly used in electrochemical processing, electroplating, corrosion research, material surface treatment, and other fields. Their core feature is the ability to rapidly change current direction (positive/negative polarity switching) to meet specific process requirements.

With programmable polarity switching capabilities, commutating reverse polarity power supplies optimize process effects, improve coating quality, and enable advanced material research in various industrial applications.

Key Features of Commutating Reverse Polarity Power Supplies

Rapid Polarity Switching

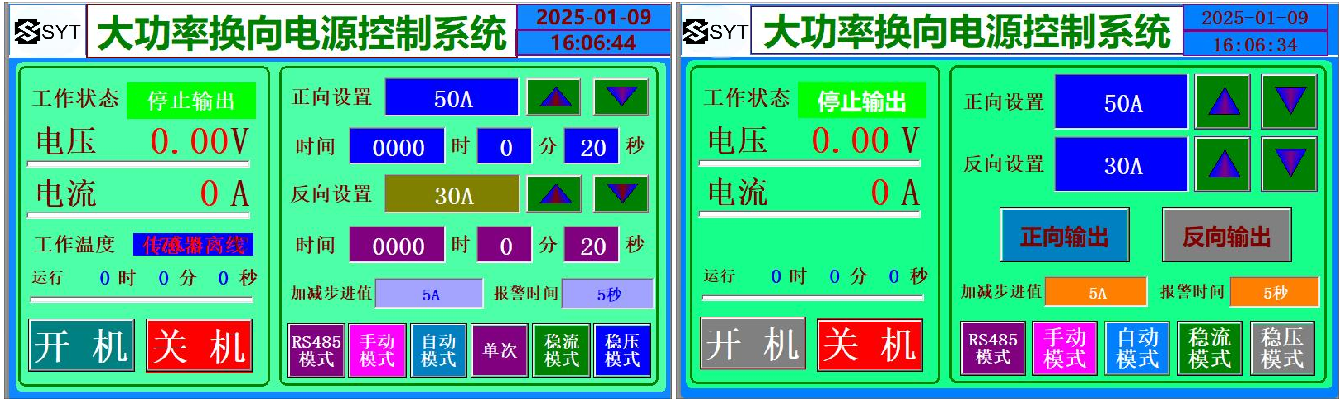

Output voltage can switch between positive and negative polarities with short switching times (milliseconds to seconds), ideal for applications requiring periodic current direction changes.

Controlled Current Direction

Supports constant current (CC), constant voltage (CV), or pulse modes with programmable control over switching time, duty cycle, and other parameters.

Low Ripple & High Stability

Utilizes high-frequency switching or linear regulation technology to ensure stable output current/voltage, minimizing process impact for high-precision applications.

Comprehensive Protection

Features overcurrent, overvoltage, short-circuit, and overheating protection to prevent equipment damage during polarity switching, with soft-start capability in advanced models.

Programmable Control

Modern commutating reverse polarity power supplies support external triggering (PLC, PC control) for automated switching, making them suitable for industrial production lines. Parameters such as switching cycle, duty cycle, and current/voltage amplitude can be precisely set.

Typical Applications

These specialized power supplies find applications across multiple industries:

- Electroplating Industry: Pulse reverse plating (PRC) improves coating uniformity, reduces porosity, and enhances adhesion for precious metals, PCB copper plating, and nickel coatings

- Electrochemical Machining (ECM): Electrolytic deburring and precision polishing of stainless steel, titanium alloys, and other materials

- Corrosion Research & Protection: Cathodic protection for metal structures and corrosion testing under varying current conditions

- Battery & Material Research: Testing lithium/sodium-ion batteries and electrochemical deposition for nanomaterials and thin films

- Other Industrial Applications: Electromagnet control for magnetization/demagnetization processes and plasma treatment for surface modification in semiconductor and photovoltaic industries

Selection Considerations

When choosing a commutating reverse polarity power supply, consider these key factors:

- Output Parameters: Voltage/current range, switching speed, and duty cycle adjustment capability

- Control Methods: Manual adjustment, external triggering (TTL/PWM), or computer control (RS485/RS232/GPIB/USB)

- Protection Features: Comprehensive protection functions and soft-start capability

- Application Matching: Select appropriate power and switching frequency based on specific process requirements

Technical Advice

For optimal performance, match the power supply specifications to your specific application requirements. SYT offers a range of commutating reverse polarity power supplies with customization options to meet diverse industrial needs.